Evaluating Recycled Glass Substrate for Sustainable Tank Flooring

Introduction to Recycled Glass Substrate

Recycled glass substrate is emerging as a sustainable alternative for various construction applications, including tank flooring. This innovative material is derived from post-consumer and industrial glass waste, which is processed into a granular form suitable for structural use. As industries seek eco-friendly solutions, recycled glass substrate offers a compelling option that combines environmental benefits with practical performance. This article explores its potential, focusing on its application in tank flooring systems.

Environmental Benefits of Using Recycled Glass

One of the most significant advantages of recycled glass substrate is its positive environmental impact. By repurposing glass waste, this material reduces landfill contributions and conserves natural resources. Traditional flooring materials often rely on mining or quarrying, which can lead to habitat destruction and increased carbon emissions. In contrast, recycled glass substrate requires less energy to produce and contributes to a circular economy. Additionally, its use in tank flooring can help industries meet sustainability goals and comply with environmental regulations.

Technical Properties of Recycled Glass Substrate

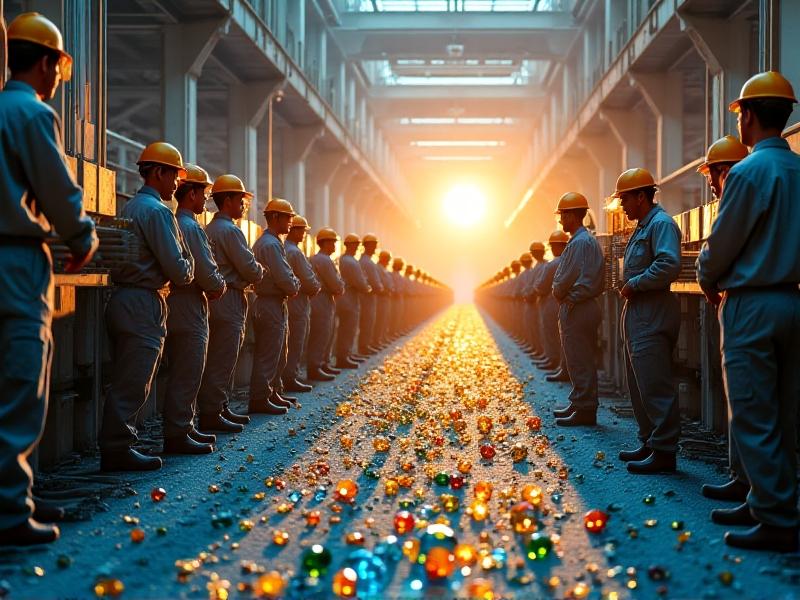

Recycled glass substrate is not just environmentally friendly; it also boasts impressive technical properties. Its granular structure provides excellent drainage capabilities, making it ideal for tank flooring where moisture control is critical. The material is also highly durable, resistant to chemical corrosion, and capable of withstanding heavy loads. These properties make it a viable alternative to traditional materials like gravel or concrete. Furthermore, its aesthetic appeal, with its translucent and colorful appearance, can enhance the visual appeal of industrial spaces.

Applications in Tank Flooring Systems

Tank flooring systems require materials that can endure harsh conditions while providing stability and functionality. Recycled glass substrate meets these requirements by offering a lightweight yet robust solution. Its drainage properties prevent water accumulation, reducing the risk of corrosion and structural damage. Additionally, its chemical resistance makes it suitable for tanks storing liquids like acids or alkalis. Case studies from industries such as wastewater treatment and chemical storage highlight its effectiveness in real-world applications, demonstrating its potential as a sustainable flooring option.

Challenges and Limitations

While recycled glass substrate offers numerous benefits, it is not without challenges. One concern is the availability of high-quality glass waste, as contaminants can affect the material’s performance. Processing costs and the need for specialized equipment can also be barriers to widespread adoption. Additionally, there is a learning curve for contractors unfamiliar with the material, which may slow its integration into mainstream construction practices. Addressing these challenges through research, innovation, and education will be crucial for maximizing its potential.

Comparative Analysis with Traditional Materials

To evaluate the viability of recycled glass substrate, it is essential to compare it with traditional flooring materials like gravel, concrete, and sand. While these materials have long been the standard, they often come with environmental and performance drawbacks. Recycled glass substrate offers comparable strength and durability while providing additional benefits such as improved drainage and aesthetic appeal. Cost comparisons reveal that, although initial expenses may be higher, the long-term savings in maintenance and environmental impact make it a worthwhile investment.

Future Prospects and Innovations

The future of recycled glass substrate looks promising, with ongoing research and development aimed at overcoming its limitations. Innovations in processing techniques are improving the quality and consistency of the material, making it more accessible to industries. Collaborations between manufacturers, researchers, and policymakers are also driving its adoption. As awareness of its benefits grows, recycled glass substrate is poised to become a mainstream choice for sustainable construction, particularly in specialized applications like tank flooring.

Conclusion: The Path Forward for Sustainable Tank Flooring

Recycled glass substrate represents a significant step forward in sustainable construction, particularly for tank flooring systems. Its environmental benefits, technical properties, and practical applications make it a compelling alternative to traditional materials. While challenges remain, ongoing innovations and increased awareness are paving the way for its widespread adoption. By embracing this eco-friendly solution, industries can reduce their environmental footprint while maintaining high performance and durability in their infrastructure.